Lapidary work is an art form that has been around for centuries. It involves cutting, shaping, and polishing stones to create beautiful jewelry and other decorative pieces. One of the most important tools in lapidary work is the diamond wheel or lap. These tools are essential for grinding, shaping, and polishing stones to perfection. In this ultimate guide, we will explore the different types of diamond wheels and laps, their advantages over traditional lapidary tools, how to choose the right one for your project, and much more.

Types of Diamond Wheels and Laps

There are several different types of diamond wheels and laps available in the market. Each type has its own advantages and disadvantages, depending on the type of lapidary work you are doing.

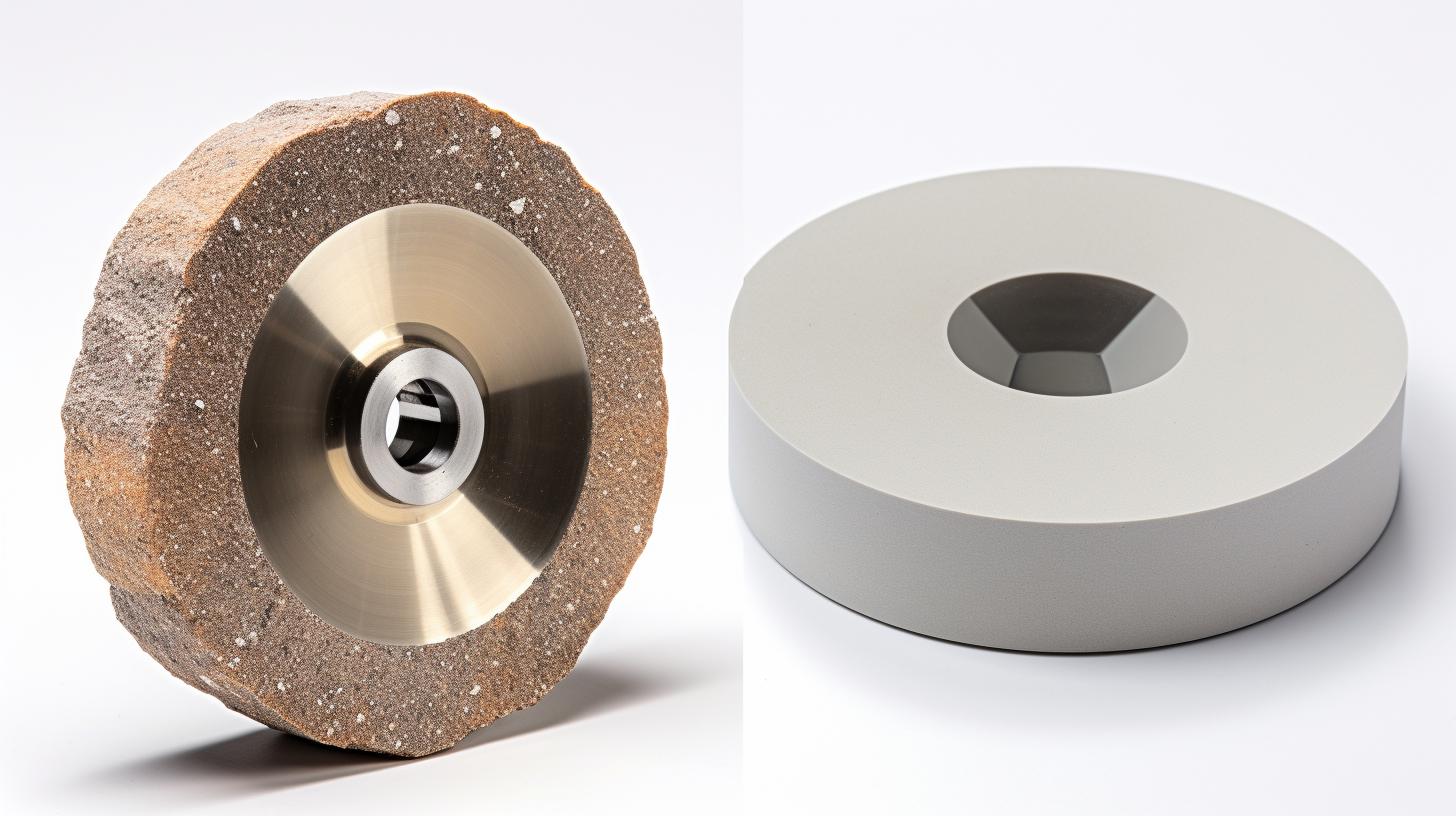

Electroplated Diamond Wheels and Laps

Electroplated diamond wheels and laps are made by coating a layer of diamonds onto a metal wheel or lap using an electroplating process. These tools are affordable and easy to use, making them a popular choice for beginners. They are also versatile and can be used for both wet and dry grinding. However, they tend to wear out quickly and may not be suitable for heavy-duty grinding.

Sintered Diamond Wheels and Laps

Sintered diamond wheels and laps are made by fusing diamond particles with metal powder under high heat and pressure. These tools are known for their durability and long lifespan. They are ideal for heavy-duty grinding and can be used for both wet and dry grinding. However, they tend to be more expensive than other types of diamond wheels and laps.

Resin-bonded Diamond Wheels and Laps

Resin-bonded diamond wheels and laps are made by bonding diamond particles together using a resin binder. These tools are affordable and easy to use, making them a popular choice for beginners. They are also versatile and can be used for both wet and dry grinding. However, they tend to wear out quickly and may not be suitable for heavy-duty grinding.

Hybrid Diamond Wheels and Laps

Hybrid diamond wheels and laps are a combination of two or more types of diamond wheels and laps. These tools are designed to provide the benefits of each type of diamond wheel or lap while minimizing their drawbacks. They are ideal for those who need a versatile tool that can handle a variety of lapidary work.

Comparison of Different Types of Diamond Wheels and Laps

Each type of diamond wheel and lap has its own advantages and disadvantages. When choosing the right one for your project, consider factors such as the type of stone you are working with, the stage of lapidary work you are in, and your budget. It is also important to choose a reputable brand and manufacturer, such as CabKing’s diamond laps or Cutting Edge Supply’s faceting laps.

Key Takeaways

- Diamond wheels and laps are essential tools in lapidary work, providing speed, accuracy, and versatility.

- There are different types of diamond wheels and laps, including electroplated, sintered, resin-bonded, and hybrid options.

- Factors to consider when choosing the right diamond wheel or lap include grit size, diamond concentration, and bonding types.

Advantages of Using Diamond Wheels and Laps over Traditional Lapidary Tools

Diamond wheels and laps offer several advantages over traditional lapidary tools such as silicon carbide wheels and polishing discs.

Speed and Efficiency

Diamond wheels and laps are much faster and more efficient than traditional lapidary tools. They can grind, shape, and polish stones in a fraction of the time it would take with other tools. This makes them ideal for those who want to complete their lapidary work quickly and efficiently.

Accuracy and Precision

Diamond wheels and laps are also more accurate and precise than traditional lapidary tools. They can create perfectly flat surfaces, sharp edges, and intricate shapes with ease. This makes them ideal for those who value precision and craftsmanship in their lapidary work.

Cost-Effectiveness

While diamond wheels and laps may be more expensive than traditional lapidary tools, they are also more cost-effective in the long run. They last much longer than other tools, which means you won’t have to replace them as often. This can save you both time and money in the long run.

Versatility

Diamond wheels and laps are also much more versatile than traditional lapidary tools. They can be used for a variety of lapidary work, including grinding, shaping, and polishing. This makes them a popular choice for both beginners and experienced lapidary enthusiasts.

Comparison with Other Lapidary Tools

When compared to traditional lapidary tools such as silicon carbide wheels and polishing discs, diamond wheels and laps offer several advantages. They are faster, more accurate, and more versatile, making them a popular choice for lapidary work.

How to Choose the Right Diamond Wheel or Lap for Your Project

Choosing the right diamond wheel or lap for your project can be a daunting task. Here are some factors to consider when making your decision:

Grit Size, Diamond Concentration, and Bonding Types

The grit size, diamond concentration, and bonding types of a diamond wheel or lap can greatly affect its performance. Generally, the higher the grit size and diamond concentration, the finer the finish you can achieve. The bonding type can also affect the lifespan and performance of the tool.

The Right Diamond Wheel or Lap for Different Stages of Lapidary Work

Different stages of lapidary work require different types of diamond wheels and laps. For example, rough grinding requires a coarse grit diamond wheel, while polishing requires a fine grit diamond lap. It is important to choose the right tool for each stage of your lapidary work.

Comparison of Different Diamond Wheels and Laps for Specific Projects

Different diamond wheels and laps may be more suitable for specific lapidary projects. For example, CabKing’s full face diamond laps are ideal for creating flats on larger cabs, while Inland Craft’s sintered diamond laps are ideal for aggressive cutting.

How to Use Diamond Wheels and Laps for Grinding, Shaping, and Polishing Stones

Using diamond wheels and laps for grinding, shaping, and polishing stones requires some skill and technique. Here is a step-by-step guide to using these tools:

Step-by-Step Guide for Using Diamond Wheels and Laps

- Choose the right diamond wheel or lap for your project.

- Install the tool onto your lapidary machine.

- Turn on the machine and adjust the speed to the desired level.

- Place the stone onto the diamond wheel or lap and apply gentle pressure.

- Move the stone back and forth over the tool, making sure to keep it wet.

- Repeat the process with finer grit diamond wheels or laps until you achieve the desired finish.

- Clean the stone and the tool after each stage of grinding, shaping, or polishing.

Different Techniques and Methods for Using Diamond Wheels and Laps

There are several different techniques and methods for using diamond wheels and laps, depending on the type of lapidary work you are doing. For example, you may need to use a different technique for grinding rough stones than you would for polishing cabochons. It is important to research and learn the proper techniques for each type of lapidary work.

Tips for Achieving a Smooth and Polished Finish

Achieving a smooth and polished finish with diamond wheels and laps requires some skill and practice. Here are some tips to help you get the best results:

- Use the right grit-size diamond wheel or lap for each stage of your lapidary work.

- Keep the stone and the tool wet to prevent overheating and damage.

- Use gentle pressure and make sure to move the stone evenly over the tool.

- Take breaks and clean the stone and the tool after each stage of grinding, shaping, or polishing.

Comparison of Diamond Wheels and Laps for Different Stages of Lapidary Work

Different diamond wheels and laps may be more suitable for different stages of lapidary work. For example, electroplated diamond wheels may be more suitable for rough grinding, while sintered diamond laps may be more suitable for polishing.

Maintenance and Care of Diamond Wheels and Laps

Proper maintenance and care of diamond wheels and laps can greatly extend their lifespan and performance. Here are some tips for maintaining and caring for your tools:

Proper Cleaning and Storage of Diamond Wheels and Laps

After each use, clean the diamond wheel or lap with water and a mild detergent. Dry it thoroughly before storing it in a dry, clean place.

Re-Dressing Diamond Wheels and Laps

Diamond wheels and laps may need to be re-dressed from time to time to maintain their performance. This involves removing any build-up of debris or diamond particles from the surface of the tool.

Extending the Lifespan of Diamond Wheels and Laps

To extend the lifespan of your diamond wheel or lap, avoid using excessive pressure or heat when grinding, shaping, or polishing stones. Also, make sure to store the tool in a dry, clean place when not in use.

Comparison of Maintenance and Care for Different Types of Diamond Wheels and Laps

Different types of diamond wheels and laps may require different maintenance and care. For example, sintered diamond laps may require more frequent re-dressing than electroplated diamond wheels.

Top Brands and Manufacturers of Diamond Wheels and Laps

There are many top brands and manufacturers of diamond wheels and laps in the market. Some of the most popular ones include CabKing, Inland Craft, and Cutting Edge Supply. It is important to choose a reputable brand and manufacturer that offers high-quality tools at a reasonable price.

Safety Precautions When Using Diamond Wheels and Laps

Using diamond wheels and laps can be dangerous if proper safety precautions are not taken. Here are some safety tips to keep in mind:

Eye and Ear Protection

Wear safety goggles and earplugs when using diamond wheels and laps to protect your eyes and ears from flying debris and noise.

Proper Clothing and Footwear

Wear long-sleeved shirts, pants, and closed-toe shoes when using diamond wheels and laps to prevent injuries from flying debris.

Safe Operating Procedures

Follow the manufacturer’s instructions for operating the diamond wheel or lap, including proper speed, pressure, and technique.

Common Safety Hazards and How to Avoid Them

Common safety hazards when using diamond wheels and laps include flying debris, noise, and overheating. To avoid these hazards, wear protective gear, work in a well-ventilated area, and take breaks to prevent overheating.

Comparison of Safety Features for Different Types of Diamond Wheels and Laps

Different types of diamond wheels and laps may offer different safety features, such as built-in guards or cooling systems. It is important to choose a tool that offers the appropriate safety features for your lapidary work.

Frequently Asked Questions About Diamond Wheels and Laps

Here are some common questions about diamond wheels and laps:

What is a diamond wheel or lap?

A diamond wheel or lap is a tool used for grinding, shaping, and polishing stones in lapidary work.

What are the different types of diamond wheels and laps?

The different types of diamond wheels and laps include electroplated, sintered, resin-bonded, and hybrid.

How do I choose the right diamond wheel or lap for my project?

Consider factors such as the type of stone you are working with, the stage of lapidary work you are in, and your budget. It is also important to choose a reputable brand and manufacturer.

How do I use a diamond wheel or lap?

Install the tool onto your lapidary machine, turn on the machine, and place the stone onto the diamond wheel or lap. Apply gentle pressure and move the stone back and forth over the tool, making sure to keep it wet.

How do I maintain and care for my diamond wheel or lap?

Clean the tool after each use, re-dress it from time to time, and store it in a dry, clean place when not in use.

Case Study: John’s Experience with Diamond Wheels and Laps

Top Brands and Manufacturers of Diamond Wheels and Laps

When it comes to lapidary work, having the right tools is crucial for achieving the desired results. One brand that consistently stands out in terms of quality and performance is DiamondCraft. With their wide range of diamond wheels and laps, they have become a trusted name among lapidary enthusiasts.

One lapidary artist who can attest to the excellence of DiamondCraft products is John. John has been passionate about lapidary work for over a decade, and he has tried various brands of diamond wheels and laps throughout his journey. However, it wasn’t until he discovered DiamondCraft that he truly experienced a game-changer in his craft.

John’s favorite diamond wheel from DiamondCraft is their electroplated diamond wheel. He recalls a particular project where he needed to shape and polish a rare gemstone with intricate details. The electroplated diamond wheel proved to be the perfect tool for the job. Its precise cutting ability and smooth polishing action allowed John to achieve the intricate shapes and flawless finish he desired.

Impressed with the performance of the electroplated diamond wheel, John decided to explore other products from DiamondCraft. He also tried their sintered diamond wheels and laps, which proved to be excellent for grinding and shaping harder materials. The resin-bonded diamond wheels and laps, on the other hand, provided optimal results for his polishing needs.

What sets DiamondCraft apart, according to John, is not just the quality of their diamond wheels and laps, but also their dedication to customer satisfaction. Their products are competitively priced, making them accessible to both professionals and hobbyists. Additionally, DiamondCraft offers excellent customer support, ensuring that every customer is well taken care of.

John’s positive experience with DiamondCraft’s diamond wheels and laps has made him a loyal customer. He has recommended their products to fellow lapidary enthusiasts, and they too have been impressed with the results. With DiamondCraft, John has found the tools that have taken his lapidary work to new heights, and he can’t wait to see what he can create next.

Conclusion

In conclusion, diamond wheels and laps are essential tools for lapidary work. They offer several advantages over traditional lapidary tools, including speed, efficiency, accuracy, and versatility. By choosing the right diamond wheel or lap for your project, learning the proper techniques for using them, and maintaining and caring for them properly, you can create beautiful stones and jewelry that will last a lifetime. Remember to choose a reputable brand and manufacturer, such as CabKing’s diamond laps or Cutting Edge Supply’s faceting laps, and take proper safety precautions to ensure a successful and enjoyable lapidary experience.